MAINTENANCE FREE

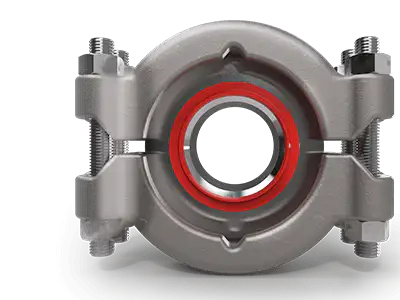

FLANGES

COMPACT

CONNECTIONS

SUBSEA TECHNOLOGY

IN A COMPACT DESIGN

360° INSTALLATION

Markets

Find the right products for your application or industry.

Offering flanges, clamps, seals, valves, receptacles and stabs for use:

Offshore:

- Subsea (X-mas trees, manifolds, pig launchers, pipeline, equipment, risers

- Topside

Onshore:

- Process plants

The products are characterized by exceptional quality, achieved through in-house machining. With over 30 years of experience, we are recognized as one of the world’s leading suppliers, providing highly compact and high-integrity solutions that reduce weight and space by approximately 30-80% compared to traditional flange solutions. Our products are capable of operating under both very high and low temperatures and pressures.

Offering customized flange, seal, and penetration solutions for containment applications in electrical equipment where watertight integrity is critical.

With our advanced design capabilities, extensive experience in machining to extreme tolerances, and in-house testing facilities, we are a world-class supplier and collaborative partner in this domain. We are actively engaged in projects related to the electrification of the NCS.

We provide flange and seal solutions for various LNG systems and plants that operate under extremely low temperatures and are subjected to significant temperature and pressure gradients.

Our high-quality, in-house machined flanges and seals, rigorously tested in our dedicated facilities, ensure a safe, reliable, and leak-free solution for our clients. Our products are designed to be compact, accommodating applications where weight and space constraints are critical.

Offering flanges specially designed and tested for use in :

- wind turbine towers

- transition pieces

- bolted floating wind structures securing higher strength capacity compared to traditional flange design used in the wind industry,

Securing : - higher strength capacity compared to traditional flange design used in the wind industry,

- a more efficient and safe assembly and installation

- a maintenance free solution during operation

The developed design is based on principles and experience from delivering flanges to O&G systems exposed to harsh environment for more than 30 years. Relevant flange diameters are from 0,5 m – 10 m. We are in the lead among flange suppliers taking our proven technology and experience from the O&G industry to the wind industry together with our customers.

Suitable products :

We offer advanced flanges and sealing solutions specifically engineered to meet the demanding requirements of nuclear applications. Each solution is designed with precision, delivering a lightweight and compact footprint while maintaining performance levels that meet or exceed traditional ASME and API standards.

Our flange technology is optimized for static behavior, providing long-term stability in high-temperature and high-pressure environments, where safety, reliability, and compliance are critical.

Addressing the Nuclear challenge

A well-known flange challenge within nuclear environments is creep and relaxation at elevated temperatures. Our flange technology is specifically designed to address these effects, ensuring dimensional stability, load retention, and leak-free sealing throughout the operating life.

Qualification and in house capabilities

We maintain comprehensive in-house testing and qualification capabilities, enabling validation against nuclear standards and project-specific requirements, including ASME III Division 5, materials testing, stress and strain evaluation, pressure and fatigue testing, high and low-temperature testing, hydrostatic testing, bending, and structural integrity.

Examples on projects we’ve delivered:

- Materials: 316 stainless steel and Alloy 625

- Dimensions: 6” – 10”

- Certification: EN 10204 3.1

Proven high-temperature and pressure performance in Nuclear:

Our solutions are validated for severe nuclear operating conditions, including:

370 °C at 250 bar(g) 585 °C at 193 bar(g) 600 °C at 400 bar(g)

Explore our range of flange types to determine the optimal solution for your specific nuclear application or consult our experts to support your qualification process.

Suitable products :

We offer a comprehensive range of flanges, clamps, and sealing solutions engineered for the most demanding hydrogen environments. Every solution is designed with precision to ensure reliability, performance, and long‑term integrity under extreme operating conditions.

Safety is paramount

Our proven leak-free technologies help mitigate risks and support safe handling and operations across high-pressure and high-temperature applications.

Examples on projects we’ve delivered:

- Materials: 316 stainless steel

- Dimensions: 1” – 6”

- Certification: EN 10204 3.1 inspection certificates

Proven temperature and pressure performance in Hydrogen:

Our solutions are validated for severe hydrogen operating conditions, including:

290 bar(g) at 250 °C 500 bar(g) at 100 °C 690 bar(g) at 200 °C

Explore our range of flange types to determine the optimal solution for your specific hydrogen application or consult our experts to support your qualification process.

We provide customized connection and valve solutions for various industries that require high integrity and compact designs, capable of operating under a diverse range of temperatures, pressures, and media.

Offering flanges, clamps, seals, valves, receptacles and stabs for use:

Offshore:

- Subsea (X-mas trees, manifolds, pig launchers, pipeline, equipment, risers

- Topside

Onshore:

- Process plants

The products are characterized by exceptional quality, achieved through in-house machining. With over 30 years of experience, we are recognized as one of the world’s leading suppliers, providing highly compact and high-integrity solutions that reduce weight and space by approximately 30-80% compared to traditional flange solutions. Our products are capable of operating under both very high and low temperatures and pressures.

Offering customized flange, seal, and penetration solutions for containment applications in electrical equipment where watertight integrity is critical.

With our advanced design capabilities, extensive experience in machining to extreme tolerances, and in-house testing facilities, we are a world-class supplier and collaborative partner in this domain. We are actively engaged in projects related to the electrification of the NCS.

We provide flange and seal solutions for various LNG systems and plants that operate under extremely low temperatures and are subjected to significant temperature and pressure gradients.

Our high-quality, in-house machined flanges and seals, rigorously tested in our dedicated facilities, ensure a safe, reliable, and leak-free solution for our clients. Our products are designed to be compact, accommodating applications where weight and space constraints are critical.

Offering flanges specially designed and tested for use in :

- wind turbine towers

- transition pieces

- bolted floating wind structures securing higher strength capacity compared to traditional flange design used in the wind industry,

Securing : - higher strength capacity compared to traditional flange design used in the wind industry,

- a more efficient and safe assembly and installation

- a maintenance free solution during operation

The developed design is based on principles and experience from delivering flanges to O&G systems exposed to harsh environment for more than 30 years. Relevant flange diameters are from 0,5 m – 10 m. We are in the lead among flange suppliers taking our proven technology and experience from the O&G industry to the wind industry together with our customers.

Suitable products :

We offer advanced flanges and sealing solutions specifically engineered to meet the demanding requirements of nuclear applications. Each solution is designed with precision, delivering a lightweight and compact footprint while maintaining performance levels that meet or exceed traditional ASME and API standards.

Our flange technology is optimized for static behavior, providing long-term stability in high-temperature and high-pressure environments, where safety, reliability, and compliance are critical.

Addressing the Nuclear challenge

A well-known flange challenge within nuclear environments is creep and relaxation at elevated temperatures. Our flange technology is specifically designed to address these effects, ensuring dimensional stability, load retention, and leak-free sealing throughout the operating life.

Qualification and in house capabilities

We maintain comprehensive in-house testing and qualification capabilities, enabling validation against nuclear standards and project-specific requirements, including ASME III Division 5, materials testing, stress and strain evaluation, pressure and fatigue testing, high and low-temperature testing, hydrostatic testing, bending, and structural integrity.

Examples on projects we’ve delivered:

- Materials: 316 stainless steel and Alloy 625

- Dimensions: 6” – 10”

- Certification: EN 10204 3.1

Proven high-temperature and pressure performance in Nuclear:

Our solutions are validated for severe nuclear operating conditions, including:

370 °C at 250 bar(g) 585 °C at 193 bar(g) 600 °C at 400 bar(g)

Explore our range of flange types to determine the optimal solution for your specific nuclear application or consult our experts to support your qualification process.

Suitable products :

We offer a comprehensive range of flanges, clamps, and sealing solutions engineered for the most demanding hydrogen environments. Every solution is designed with precision to ensure reliability, performance, and long‑term integrity under extreme operating conditions.

Safety is paramount

Our proven leak-free technologies help mitigate risks and support safe handling and operations across high-pressure and high-temperature applications.

Examples on projects we’ve delivered:

- Materials: 316 stainless steel

- Dimensions: 1” – 6”

- Certification: EN 10204 3.1 inspection certificates

Proven temperature and pressure performance in Hydrogen:

Our solutions are validated for severe hydrogen operating conditions, including:

290 bar(g) at 250 °C 500 bar(g) at 100 °C 690 bar(g) at 200 °C

Explore our range of flange types to determine the optimal solution for your specific hydrogen application or consult our experts to support your qualification process.

We provide customized connection and valve solutions for various industries that require high integrity and compact designs, capable of operating under a diverse range of temperatures, pressures, and media.

Manufactured with 100% green energy

TP-Products is proud to annouce that we have been certified as an eco-friendly green manufacturer using only power produced from renewable energy sources … contributing to a more sustainable world !

TP-Products supplies valves and flanges for the entire energy chain

driving efficient and sustainable operations.

Wind Turbine Tower Flange

Wind Power Flanges

Wind Turbine Structural

Fundament Flange

Subsea Canister

Risers

TPC Compact Flange

Risers

TPC Compact Flange

Wind Turbine Tower Flange

Wind Power Flanges